HSLA & AHSS Press Feed Lines

HSLA & AHSS Press Feed Lines

Innovative, cost-effective coil processing solutions.

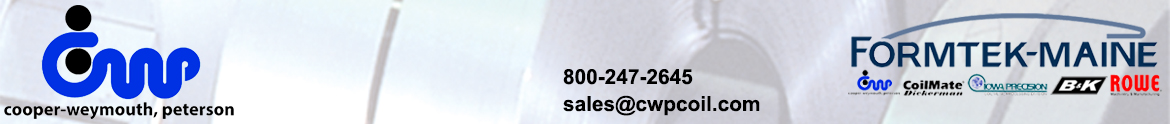

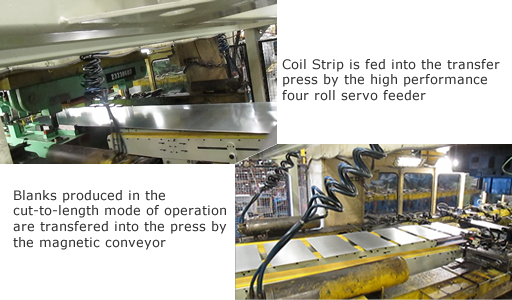

Press Feed Lines designed to process High Strength Low Alloy or Advanced High Strength Steels (HSLA or AHSS). To flatten material, the straightener rolls must be able to work the material beyond its yield point. Materials in the HSLA and AHSS families have much higher yield points than conventional steel, therefore a smaller work roll and greater roll penetration into the material is required to work the material beyond the yield point. But, due to the forces required to straighten the high strength materials, straightener roll deflection can become an issue. Over time this deflection can lead to bearing failure, broken journals or gears and create distorted(wavy edge) material. The Series 63 & 64 Straighteners are equipped with heavy-duty backup rolls to prevent straightener roll deflection. This enables moderate roll size to handle a broad range of stock widths and thicknesses which gives the machine greater versatility to flatten materials with a higher yield point like HSLA & AHSS. Straightener rolls have been designed with oversized journals and utilize a high-strength Alloy steel. The Tensile strength of our rolls is 24,000PSI greater than competitive machines built with the industry standard 1045 Steel. Straightener side frames are a full 3" thick and incorporate dual high capacity bearings. Outboard journal supports provide outstanding rigidity to handle the higher horsepower and torque required to straighten these high strength materials.  50,000LB by .125" thick AHSS Transfer Press feed line The 72" wide Trifunction Transfer Press Feed Line shown above incorporates a Hydraulic Cut to Length Production Shear and a Blank Destacker to allow continuous coil, rectangular blanks or developed blank feeding from the same system. A Servodriven Magnetic Conveyor transfers blanks created in the cut to length mode or developed blanks that have been destacked onto the conveyor in the destack mode into the Transfer Press. A Four Roll Servo Feeder is utilized to accurately feed the coil strip into the Transfer Press or the Hydraulic Shear. The CWP Trifunction system provides the ultimate in flexibility for your Transfer Press. A Trapezoidal Shear with Part Rotator option is available to allow processing of trapezoid blanks.  Processing HSLA & AHSS Materials   The Trifunction Press Feed Line is equipped with a Total System Control automation package to set up the system based on a pre-programmed job or part number. Feed progression, speed, straightener head settings, material width for stock guide location, uncoiler brake tension and magnetic conveyor settings are all stored in memory for each job. The control can also calculate initial straightener roll depth settings based on material parameters removing the guesswork.  72" Dual Function Transfer Press Line 72" Dual Function Transfer Press Line above is capable of processing HSLA & AHSS up to .280" thick. The line incorporates a Blank Destacker and a traveling 4-roll Servo Feeder which is utilized to accurately feed coil strip while in position. The servo feeder can travel to the front side of the line while a stack of developed blanks travels in from the back of the line to allow blank destack operation and Dual Function Flexibility. A secondary hydraulic hold down arm is provided to ensure safe thread up of advanced high strength steels.  72" HSLA Transfer Press Line 72" wide HSLA or AHSS coils up to .125" thickness can be processed on this Transfer Press Feed Line. A precision 6-3 Coil Straightener with 11 backed up straightener rolls is incorporated to allow production of panel flat blanks, while a 4-Roll Servofeeder ensures precise accuracy.  50,000 Lb. HSLA or AHSS coils up to .187" thickness can be processed on this 84" wide Transfer Press Line. This Transfer Press system solution for a major automotive parts supplier is designed for high performance and accuracy. The line features a Total System Automated Control to set up the system based on a pre-programmed job or part number and a four-roll servofeed allowing for +/- .002" accuracy. The coil processing system is equipped with heavy-duty debender, knurled thread-up rolls, backed up chrome straightener rolls and ultrasonic variable tension brake control. Our exclusive "Auto-Ready" and diagnostic system allows hands-free thread-up and processing of 84" x .187" material by one operator. |