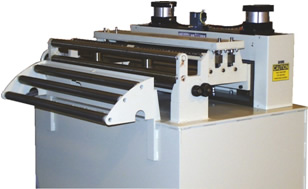

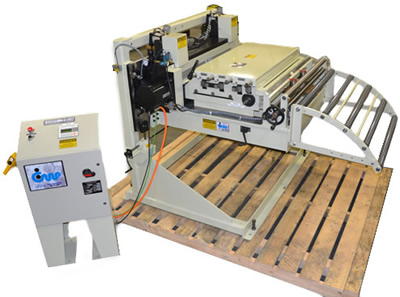

ServoMax© Servo Feed With Pull Through Straightener

CWP SERVO ROLL FEEDS equipped with PULL THROUGH STRAIGHTENERS save floor space |

|

|

The addition of a pull-thru straightener to a ServoMax© Servofeed is a cost saving design that saves floor space when compared to a conventional press feed line equipped with a power driven straightener. A servo feeder equipped with a pull-through straightener can also help reduce material scrap and reduce downtime. As a coil of material is depleted during operation, the coil set increases as the OD decreases. This change in coil set may require deeper roll penetration to produce an acceptable flat part. The pull-thru straightener is located right in front of the servo feeder. Therefore adjustments to the pull-thru straightener improve the quality of the part almost immediately reducing material jams and scraped parts.  ServoMax© Servofeed equipped with a heavy-duty servo drive and motor to provide the power to pull material thru the SM5 pull thru straightener  Servomax© H servo feeder with a SXM5 pull thru straightener capable of accurately feeding materials up to ¼" thickness. The Servomax© H servo feeder utilizes a 4:1 pivot assembly that produces 4 times more roll pressure than competitive servofeeds for superior material traction. The pull-thru straightener is equipped with air lifted pinch rolls and powered pinch rolls synchronized with the servo feed rolls for ease of thread-up. An automatic lubrication system and adjustable height cabinet are also included.  Servomax© H servo feeder with a SXM7 seven roll pull thru straightener mounted on an adjustable height feed stand Available Options – Pull-Thru straightener:

Please consult the factory for details, with your specific job requirements. |

|